Setting the record straight…

Welcome to The Wheelwright Blog.

In this blog I want to record some of the knowledge I have found out about wheelwrighting but also to set the record straight regarding good and bad practice in today’s world.

A little update about me…

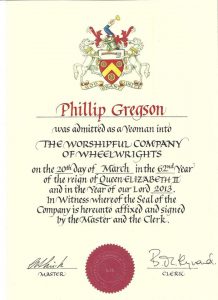

I’m Phill Gregson CF, Master Wheelwright, Yeoman of the Worshipful Company of Wheelwrights. CF stands for Churchill Fellow (granted with respect to the research I have undertaken in the field of Wheelwrighting).

It’s a bit of a mouth full I know but I’m very proud of my achievements and accreditation.

Most importantly though, as a working wheelwright, are the practical skills and abilities I have to hand, not only consisting of my own experiences from over 20 years in the wheelwright’s shop but there’s also currently over 200 years of living wheelwright knowledge in my workshop and it goes back for four direct generations. So, I would hope that I have a relative wheel making encyclopedia to hand.

The key thing is that, despite all the knowledge I have to hand, I always have a thirst for more, hence the Worldwidewheelwright project and my current ongoing research into material testing, strengths, stresses and engineering strength traits in traditional wooden wheels.

So, I think that’s enough about me for now, let’s get going…

The wooden wheel is considered by some to be one of the greatest inventions in the history of great inventions. One could argue that without the wheel we would have pretty much none of the inventions that developed since approx. 5000BC.

This may seem a bold claim, but think about it for a moment, the wheel features in everything we see around us, it heavily features in very simple early pottery and art for good reason. You probably would struggle to farm crops without the wheel, how else would you move your harvest? What about trade? How would you move your goods?

It would be difficult, if not almost impossible, to do all those things. Not to mention the related engineering principles, such as gears and pulleys, which are in pretty much all everyday items, that are in essence a wheel.

So from this we must consider the wheel as something extremely important, it’s history, but it’s present and future too.

Here’s where we get into my opinions and feelings a little deeper….

I have the ultimate respect for the history of the wheel and believe it is massively overlooked, simple remarks in articles such as “the wooden wheel remained pretty much unchanged since the roman era” or “the wooden wheel was no longer fit for purpose” make me sad as this simply isn’t true.

The wooden wheel has been an ever evolving piece of technology from day one, only being superseded in the early 1900’s by metal spoked or pressed out steel rims with pneumatic tyres due to manufacturing practices.

From the earliest disk type wheels such as the Ljubljana marshes wheel through to the chunky, round spoked, Oseberg Cart, then on to the Roman and Celtic metal bound or hooped wooden wheels that we consider similar to our wheels today. Then, with the retreat of the Romans from the UK in approx 500AD, the evolution of the wheel took a stepback for awhile and there was a spell of making spoked wheels without metal tyres. There are different opinions to the reasoning behind this but my opinion is that if iron was, at times, equal in value to the same weight in silver, then you’re not going to waste it on wheel tyres.

Some of the greatest advances in the wooden wheel came along late on in its history, in the form of dish, stagger and metal bearings.

Dish is made by angling all the spokes forwards to the outside face of the wheel and is used to give the wheel lateral strength. Most wheelwright’s don’t know how or why dish exists and some don’t consider it important at all but it is vital for a strong, working wheel to have a correct amount of dishing. I will explain dish further in future blogs and posts…

Stagger is made by having two rows of spokes, offset from each other to give lateral strength, a basic form of buttressing that allows the same lateral strength at the base or ‘foot’ of the spoke whilst utilising lighter spokes (smaller cross section). This helps make the wheel lighter and came to be quite popular throughout the 1800’s onwards.

Metal Bearings make the wheel more serviceable, capable of carrying heavy loads further and more easily, as well as enabling the wheel to be made lighter as a metal axle didn’t need to be as big as a wooden axle in order to carry the same weight.

I’ll go into all these points in much more detail at a later date as it would take a lot of writing to do each topic the justice it deserves.

Stop Re-inventing the wheel…

This is where I might start to rant a little, as you can probably see, the wooden wheel means a lot to me and up to recent years there’s always been a necessity for a wheel to be ‘fit for purpose‘. You may hear me prattle on about this a lot but it is the main function of a wheel to do the job it was intended for.

So throughout my career as a wheelwright I have seen trends in the type of work coming through the workshop doors.

There was a time when most of my work was for handcarts for local fruit and produce markets but they’re mostly closed down now thanks to the likes of supermarkets and online shopping. In a busy year my family firm could turn out up to 200 new and/or restored handcarts.

Then there was also a spell where I couldn’t make enough Gypsy wagon and dray wheels. Sadly, I can’t compete on price with cheaply imported sets from Poland these days, however, they could probably never compete with me on quality. To list just a few faults (a few of many); their tenons are too narrow and short which weakens the spokes laterally; the nave/hubs are too small leaving little supporting timber between the spokes; the whole wheel is produced from ash, not the traditional oak, ash and elm or even suitable alternatives; the tyres are often not tight enough and the welds/joins are regularly not filleted out before welding (so the tyres snap after a little wear on the road) and that’s not to mention the soft iron axle boxes (bearings) that seize solid onto the axles then churn their way out of the wheel, which in my opinion is one of the most dangerous points about these wheels… (deep breath and carry on)…

The next big thing that now keeps me busy is replacing the poorly made imported wheels mentioned above and the incredibly poor quality wheels made in the UK too!

My current work load is made up of around 50% repairs/replacements, of which probably half again are relatively new wheels made to an unacceptable standard.

There’s many things that anger me around these facts, I could probably write a long list but just a few of the main points will do for now.

Badly made wheels will be the death of Wheelwrighting in the UK…

Recent years have seen an increase in the amount of wooden wheels replaced by aluminium or steel wheels. Why? Because people don’t believe that wooden wheels can be fit for purpose, despite having had original wooden wheels that have lasted around 100 years. I believe this is because they have then had them repaired by an “wheelwright” to soon collapse or become very loose. The response from the “wheelwright” is “what do you expect? it’s a wooden wheel” as a way to cover the fact that their work is unacceptable and customers sadly believe them because “but they do the work for (insert respected organisation here), so they must be good“.

Luckily some of these customers make their way to my workshop instead of giving up or heading to an aluminium foundry. Although, unfortunately, by this point they have been ripped off by the previous “wheelwright” and some are thoroughly put off from having wooden wheels again in the future. One example that sticks in my mind is a comment on a Facebook post recently stating “don’t waste your money on anything with wooden wheels, you’ll be replacing the wheels every few years“. This shouldn’t be the case, I would certainly be disappointed if any wheel I made did not outlast me, if suitably cared for.

One very sad example of how poor craftsmanship is effecting the future of the wooden wheel is … The recent carriage that was gifted to the Queen for her Diamond Jubilee by Australia has aluminium wheels, described to have been chosen “due to the high cost of producing and maintaining wooden wheels“. To me this seems like one of the biggest death blows to the wooden wheel and I question what is to blame? and how we have been brought to this position? I know that these decisions and costings are not black and white but I really struggle to see how this can be the case, as above I would be extremely upset to have to revisit one of my wheels in my lifetime.

The wooden wheel…several thousand years in the breaking…

So what are the bad Wheelwrighting practices that are going on in the UK?…

There’s a long list of bad practice going on, most of which a trained eye can spot from a mile away.

Loose/poorly fitted joints… All the joints on a wheel should be tight once the tyre is on and the spokes should actually be tight into the nave/hub before the tyre is fitted. If you want to see examples of poorly fitting spokes simply Google ‘wheelwright’s in the UK’ and take a look at the photo galleries on websites, there are some shocking examples of work being showcased… hint… if there’s a gap down a mortice or under the shoulder between the spoke and the nave/hub then it is wrong. In my workshop the spoke tenons are made oversized and tapered, then driven in with a sledgehammer, no toffee hammers or just pushing them in with a bit of glue here.

If the joints aren’t tight then the wheel is compromised considerably, it may not be safe to use. It is Not fit for purpose.

Wrong wood choice… There’s some very important reasons why we use the woods we use in a wheel. Elm doesn’t split easily so we use it for the nave/hub as it resists splitting to pieces when we drive the oversized spoke tenons into the mortices. There are few suitable replacements for elm and I only recommend substitutes when absolutely necessary (I use utile as it has a similar interwoven grain to elm but it is completely unsuitable for other parts of the wheel due to its low cross grain strength and medium crush strength).

The spokes are made from oak (or hickory in the case of some American, mass-produced wheels and beech in some military wheels due to only having a low life expectancy and not lasting long enough to rot). George Sturt wrote in his famous book The Wheelwright’s Shop of spokes being “invariably of oak” and for good reason, oak doesn’t bend or distort under load and lateral forces, so the wheel stays upright, rigid, true and strong. If the spokes flex or bend, the forces aren’t kept between the wheel components, the wheel becomes loose and therefore compromised/unsafe or Not fit for purpose.

The felloes (curved outer segments) are pretty much always made of ash in the UK although I have seen some alternatives such as beech, wych elm and oak used on old wheels, they tend not to have lasted well. We use ash because it is springy, it gives the wheel a basic, built in form of suspension and stops any shocks from the road destroying the wheel. These excellent properties mean that ash is not suitable for other parts of the wheel. I’m seeing a lot of cheap, imported hardwoods such as seraya used to replace felloes. This is one of the worst choices of wood for any part of the wheel as it has a medium crushing and bending strength combined with low shock resistance and poor resistance to decay. It is very cheap and is often cheaper than good quality softwood. It seems to be a simple matter of profit driven corner cutting. One example of why people use these woods is “I just tell them it’s mahogany, then they think it’s good quality” or “they never know the difference when it is painted” well personally I think you should be reported to trading standards as you are ripping people off,not to mention it is not fit for purpose.

“Mahogany Wheels”

Don’t be conned by the story that they’ll make your wheels from “mahogany” when in truth most cheaply imported, red coloured woods from West Africa are labelled as a “false mahogany” or “african mahogany”. True mahogany is subject to import restrictions and generally unobtainable in the UK. People often unfortunately confuse the word ‘mahogany’ as a sign of quality like using “solid oak” when in fact every timber has its strengths and weaknesses, which make them suited to specific purposes.

We have been using elm for naves, oak for spokes and ash for felloes for thousands of years for good reason, if the Victorians thought that “mahogany” was better for wheels then they certainly had plenty of it and would have used it.

So maybe I prattled on a bit too much for one little blog, but, I do feel it is important to get people up to speed with the issues we face today.

I’ll do my best to make the next blog a little more interesting and focused on interest points around the wheel as well as my current work load.

If you have taken the time to read this, thank you for paying attention!

Phill

Wheelwright to Williamsburg…

Today has been a day filled mostly with beautiful scenery on my journey from Newark, DE, where I spent the first night, to Colonial Williamsburg, VA. My first impressions of the United States are BIG, everything is massive compared to England from the vehicles on the road to the rivers I have crossed and this even extends to the food portions. I think I’m going to weigh a little bit more when I return home!

I arrived yesterday at Philadelphia International Airport to torrential rain, flooding and heavy traffic. Not an ideal situation for reacquainting myself with the ‘wrong’ side of the road, but after a slightly shaky start I soon found my, albeit very wet, feet. After a 40 minute drive to Newark, DE and a Walmart Supercenter, I found myself in a hotel for the night, ready for a good rest before the journey would really begin.

The morning dawned clear and bright (and hot!), much to my delight and I headed off south, excited to reach my first destination, Colonial Williamsburg. Along the way I have started to fall in love with this beautiful country. Passing many miles of corn fields, woodlands and big red barns it is indeed like the movies. Chesapeake Bay and the Potomac River were sights to behold. I was even admiring the American trucks on the road.

Five hours after leaving Newark I arrived at the next hotel, which will be home for the next week. I wandered around the historic quarter this evening, a chance to get to know the area a little before I start ‘work’ tomorrow and it is amazing! A local woman serving in one of the historic taverns informed me of the fact that Colonial Williamsburg is the biggest living museum in the Northern Hemisphere and in true American style it is BIG. Walking the length of the main street took at least 20 minutes (I am only guessing as I was distracted by the many wonderful sights) and there are many side streets yet to explore. It strikes me as a shame that we have nothing of this calibre back in the UK even though our history is so rich and so ancient, I feel that history is taken for granted at home.

After rounding up the night with a pint of Old Stitch Ale at Chowning’s Tavern and a short meander back to the hotel, it’s early to bed for a fresh start in the morning to meet the Wheelwrights of Colonial Williamsburg, something I’m really looking forwards to.

Day 2

Colonial Wheelwrighting day 1

Today is the day! Woke up super early (the jet lag I’m sure, definitely nothing to do with excitement), sun streaming through the curtains and the heat already starting to build, thank goodness for air conditioning. After another leisurely stroll through the historic town, I turned towards the Deane Shop (Colonial Williamsburg Wheelwright’s Shop) set back from the bustling town centre , down a side street off the lawn in front of the Governor’s Palace. It may be in a little quiet corner of the town but this establishment is by no means quiet in any sense of the word. It is a hub of noise and a delightful attraction for the public. Upon arrival I met the three full time wheelwrights, a Master (John Boag) and two Journeymen (Paul Josef Zelesnikar and Andrew de Lisle), and a volunteer called Alan who mixes most of the paints for the shop. It was encouraging and a delight to find like-minded individuals with whom I could discuss all manner of things wheelwrighting. The tour of the shop was enlightening and informative and it was good to finally meet these people and see the place in person after months of internet contact.

I was then whisked off to to the costume department and emerged, as a butterfly from a cocoon (or that’s how I imagine it), a dashing 18th century Master Wheelwright. The clothing is surprisingly comfortable and considering the hot environment, surprisingly cool and easy to work in.

Next, came a tour of the town, where John introduced me to several people that work in different trades within the foundation. It was inspirational to see such a mix of traditional skills in one place, cherished and nurtured. The atmosphere is one of passion and determination. Remember that these people are not actors, they may be in costume but the work they are doing is as every bit real as it ever was.

After a spot of lunch in the Merchant’s Quarter, the afternoon was filled with excitable conversation and a little bit of hard work. My first job on site was to adze the inside of a felloe (the outer wooden curved part of the wheel), and this required skills that I had long since forgotten. I like to think it didn’t take too long to get back into the swing of things but I am certainly not yet up to the same standard as the native Wheelwrights.

Today dawned slightly cloudy and cooler than yesterday, not that I am complaining, it is still warmer and more humid than home! I started the day slightly off kilter after eating the largest stack of pancakes and apples known to man, I appear to still be adapting to the portion sizes here.

The walk to the shop, which I enjoy very much, did little to sort me out. I fought through the post-breakfast slump by picking up a hammer and neatening up some strakes for a cannon wheel. The majority of the wheels I do in the UK are ‘hooped’ with a continuous steel tyre. In the 18th Century, there were continuous hoops around but there were also strakes. Strakes are short lengths of iron that are nailed onto the outside of the felloes, over the joints, and take the place of a hoop. There are the same number of strakes as felloes and this is equal to half the number of spokes in a wheel. For example, in these cannon wheels that the Wheelwrights are building there are 10 spokes, 5 felloes and 5 strakes per wheel. The strakes and nails had been prepared by the on-site Blacksmiths but just required a little bit of tweaking to fit the wheel perfectly. This involves altering the curvature of the iron strake by hitting it with a hammer whilst the metal is cold. If the metal was hot, it might easily kink instead of bending evenly. This sounds easy enough but the iron tends to have areas of different resistance and can need a lot of belting to achieve the shape we need!

I had the opportunity to visit the Blacksmiths shop and see some of them in action. Plus, I also managed to fit in a visit to the gunsmith, somewhere I will definitely try to get back during the rest of my stay.

Something that has stood out to me during today, is the way the Colonial Williamsburg Wheelwright’s interact with the public, something known as interpretation here. They are very engaging and it is a pleasure listening to the explanations other experts in the field use. I often talk to the public when I’m demonstrating the craft at fairs and events in the UK and will be sure to note down some of the key phrases used here to try on my fellow countrymen. It is a rare and enjoyable opportunity to see this from the other side, as the listener rather than the demonstrator.

As another day dawned over Colonial Williamsburg I find myself waking early in anticipation of the day ahead, anyone who knows me well will know I’m not much of a morning person but I’m finding myself so excited to get to the Wheelwrights shop and to take the walk through town. This walk to ‘work’ is like no other could be, at this time in the morning the streets are bustling with men and women in period dress going about their business, every one with great purpose and dedication yet still taking the time to welcome and greet one another whilst going about their day. At this time of day there are very few members of the public on site despite the town being open 24/7, I have at times been walking along with nothing out of period in sight, a strangely exciting moment that feels as though I am truly in the 18th century. I can’t emphasise enough how spiritual (for want of a better word) this experience has become, I expected my stay here to be interesting of course and intended to be a reference point as to the earliest developments of the Wheelwrights skills in this country but it has become much more than that. The wheelwrights here are truly dedicated to getting it right and I know I am probably risking becoming repetitive but I am so impressed at the purist attitude I have encountered. <a href=”http://www.worldwidewheelwright.com/wp-content/uploads/2014/08/Emily-and-Jenny.jpg”><img class=”aligncenter size-medium wp-image-135″ src=”http://www.worldwidewheelwright.com/wp-content/uploads/2014/08/Emily-and-Jenny-300×200.jpg” alt=”Emily and Jenny” width=”300″ height=”200″ /></a>

Today I have been very well entertained, in the morning the Wheelwrights had prepared some wheels for me to hoop with them (also known as tyring, ringing, bonding etc depending on your area). These wheels were very lightweight spindly, tall wheels with a narrow tyre, this kind of job I dislike back home thanks to the pliability of the narrow hoop section that can easily be buckled. It was satisfying to help with this task as the Colonial Williamsburg Wheelwrights are up against the same issues as myself and have very similar methods of overcoming any adversities. The rest of the day was spent axing out cleft timber into squared up sections to form parts for a handcart that the Wheelwrights are currently building. Cleft timber is riven/split out of a round log with a froe, wedges and/or axes, the timber is then triangular or trapezoidal in section as a result, this being a method used for reducing timber down for many other crafts and trades as well as Wheelwrighting. These cleft sections, in this case of American White oak (or a possible hybrid as pointed out by Paul the Journeyman) would then be seasoned/dried for an average of a year per inch in thickness. In modern circumstances we have moisture meters to determine the moisture content of the wood, I personally work at an average of 10% to reduce the risk of shrinkage. Other than the use of modern testing equipment our stance on the drying process is pretty much the same, a comforting indicator that though continents apart important factors remain the same.<a href=”http://www.worldwidewheelwright.com/wp-content/uploads/2014/08/Me-and-Emily-in-outfit.jpg”><img class=”aligncenter size-medium wp-image-137″ src=”http://www.worldwidewheelwright.com/wp-content/uploads/2014/08/DSCF2424-300×200.jpg” alt=”DSCF2424″ width=”300″ height=”200″ />

</a>

John, Paul and Andrew had already shown me their “stash” of cleft oak billets in a drying shed, aged about 3 years, dry, crisp and ready to use. Many of these billets are destined for use as spokes, ideal the for task at hand with beautiful straight grain, my Grandad would be so jealous if he could see the sight before me. We selected a few pieces with similar dimensions to the finished articles we would be producing, in this case 2″x 1″ rails. My part of the job was to square up the trapezoidal pieces with a side axe, a job that would be quite leisurely if the wood was green but in this case the oak was dry, hard and comparable to chopping into a lump of old iron! Once these rails were axed out, albeit after a long wait thanks to my lack of practice, Paul would expertly plane them neat, square and parallel with a wooden jack plane. <img class=”aligncenter size-medium wp-image-133″ src=”http://www.worldwidewheelwright.com/wp-content/uploads/2014/08/Me-and-Emily-in-outfit-300×200.jpg” alt=”Me and Emily in outfit” width=”300″ height=”200″ />Work seems to go so much slower here and it’s not a result of idle workers or bad practice, the almost constant stream of visitors is a massive distraction. I can imagine the constant distraction leading to regular simple mistakes (many of which I confess to making myself with little or no distraction back home). Despite this, these Wheelwrights deal with the questions, no matter how mundane, in an entertaining and informative manner with utmost decorum, true ambassadors of the trade.

After a steady days work my more than hospitable hosts held a get together, it was strange to see characters I had met over the last few days no longer wearing period costume but now in modern clothing. I have to add that I certainly wouldn’t blame them if they wore their period dress all the time as I am growing ever more comfortable in the outfit they have supplied me with. Who knows, breeches could become the next fashion trend, I know I rock the look with my “chicken legs” as described by John.

<a href=”http://www.worldwidewheelwright.com/wp-content/uploads/2014/08/DSCF2393.jpg”>

</a>

One of the highlights of the evening (besides the fantastic foods, interesting beers and quirky conversation) was the gifts bestowed upon me by my hosts, a very rare and collectable stamp depicting a Wheelwright and celebrating the Wheelwrights role in American independence, quoting “The Wheelwright, The infant Republic’s commerce and cannon rode confidently to freedom on his skills” . It is nice to see such appreciation for the Wheelwrights role despite it being in reference to the expulsion of the British empire.

The next wonderful gift was a beautiful hand forged side axe with a Hickory shaft. The axe head was forged in house at the blacksmiths shop, as a copy of an original axe head found in excavations on the site, it has a socket made from softer iron with a harder steel fire welded on for the blade, a skill that I would love to master at some point in the future. The Hickory shaft was skilfully shaped and fitted by Andrew in the Wheelwrights shop. I can’t wait to get back in the workshop on Monday and put my newest ‘toy’ to the test.

As some of my followers will know my fiancee Emily is providing support for the project, mostly acting as director of photography, filming a lot of the activities, keeping me organised and telling me off for blocking good shots by standing in front of the camera… The staff at Colonial Williamsburg have been extremely kind to Emily and myself not only giving me a great insight into the day to day of an 18th century Wheelwright but by also taking Emily under their wing. Emily has recently qualified as a Vet and to break up the monotony of filming she has spent the day with staff from Coach and Livestock and been given the opportunity to drive a pair of oxen in a wagon built by the Wheelwrights on site. I believe the best part of this was the opportunity to dress up in period clothing, a sight to behold and I honestly believe Emily fits the role well, dress and all.

<a href=”http://www.worldwidewheelwright.com/wp-content/uploads/2014/08/Emily-in-outfit-cw.jpg”><img class=”aligncenter size-medium wp-image-134″ src=”http://www.worldwidewheelwright.com/wp-content/uploads/2014/08/Emily-in-outfit-cw-300×200.jpg” alt=”Emily in outfit cw” width=”300″ height=”200″ /></a>

Sunday, a chance to unwind and reflect over the journey so far…. I wish! there’s far too much to see around here for me to slack off!

After many recommendations of places to visit whilst in the area we settled on visiting a museum in Jamestown, this being the site of the first British colony in North America. There was so much to see we could have spent days in the one museum! The exhibits take you through the story of the early attempts to settle in Jamestown, there is a reconstruction of the original fort in which the colonists faced extremes and adversities of all kinds from hostile natives to starvation.

The one thing that really strikes me is the American passion for history, I witnessed here the same dedication that I have seen at Colonial Williamsburg, professional staff and volunteers teaching the visitors with conviction and passion. I find it strange that there is so much commitment to such a brief history in comparison to our history back home, the period in which the original fort was built and occupied was pretty close to the time the Worshipful company of Wheelwrights was granted its charter. Our attitude to the vast wealth that is british history in comparison is laughable at best, and I am almost embarrassed by this.

All in all it was a wonderful day and evening, being topped off by a meal out with Paul (Journeyman Wheelwright) and his lovely wife Lynn and daughter Maggie who also would make fantastic tour guides, pointing out some interesting sights and explaining local history en route.

It’s Monday!.. Back in the workshop, and finally able to try out the beautiful axe I was given on Saturday. I often look forward to going to work (strange I know) but today was extra special, I have a new axe to play with.

The walk through town was yet again a pleasure, I didn’t expect anything else. My new axe in hand I strolled through the streets in the comfort that this was quite normal here and that people wouldn’t call the police because there’s an axe wielding ‘mad man’ walking the streets (they obviously don’t know me that well)…

Upon arrival at the Wheelwright’s shop I was welcomed in by John and Paul, this place is really beginning to feel like home and the routine is becoming extremely comfortable. I can understand why people devote their lives to working here. John is approaching 30 years working as a Wheelwright in Colonial Williamsburg and he stands before me a content man. John’s years of dedication to the craft have proven fruitful, he currently works over the two extremely skilled Journeymen he himself has trained, both capable of building beautiful wheels and vehicles in their own right. I feel inspired by this line of succession, I have for years hoped that one day I will complete the training of an apprentice and ensure the skills and knowledge bestowed on me are passed on. If they can do it here in an 18th century style facing the adversities of being bound by their period then I should be confident to (hopefully) achieve reasonable results teaching a modern Wheelwright back home.

… Anyway, back to the axe… The cleft Oak I wrote about in Saturdays blog was waiting for dressing up by hand, my opportunity to try the axe (and give it a bloody good testing) was here. The Oak was as I mentioned earlier as hard as Iron, but of course the axe performed brilliantly, comfortably and working the Oak was reasonably ‘effortless’. The side axe almost knew the job it had been made for, the fit of the shaft in my grasp, the offset of the head and the grind of the bevel working together in harmony, despite my lack of practice working with an axe. This axe is a copy of an original axe found in excavations in Colonial Williamsburg, I have no doubt that countless generations of craftsmen had evolved this axe to a nigh on perfect tool, fit for this purpose.

After a few hours of chopping I was taken to meet the Blacksmith who forged the axe head, only a young fella himself, I was pleased to see that yet again there is skill in the hands of a younger generation and that it is not just confined to the stereotypical ‘old fella’. I hasten to add that there is nothing wrong with the stereotype, I have spent most of my life surrounded by ‘old fellas’ with grey hair and bushy beards (you know who you are) and have always been grateful of the time and knowledge they have shared with me. The fact remains that young people learning crafts is generally rare but I do see attitudes changing, albeit slowly.

Tomorrow looks to be another promising day where I will have the chance to mortice some naves by hand, another task I have not partaken in for quite some time, this will be slow and painful I’m sure but at the end of the day making anything by hand is satisfying!

And another glorious day dawns over Colonial Williamsburg. In the Wheelwrights shop I found a beautiful Elm nave/hub already turned and set out for mortices, waiting for me to start work on. I had an uneasy feeling today, despite my confidence as a Wheelwright this was Andrews nave, he had selected, roughed out, turned and marked it out for morticing himself, to make a mistake on this would be catastrophic and I would never forgive myself.

I do apologise for my meanderings as I do tend to think everyone reading my blogs has an in depth understanding of Wheelwrighting and understands exactly what I am on about, I will do my best to explain the processes in a universally understandable way but please point out to me if I start babbling in Wheelwrights code!

The mortice in a nave/hub is the socket into which a spoke is fitted, generally ‘modern’ wooden wheels have parallel rectangular mortices, the general consensus is that wheels in the 1700’s would have tapered or bevelled mortices, also known as plug mortices. These bevelled mortices are hand cut and are shaped to receive the trapezoid shaped spokes I talked about in my earlier blogs whilst also being angled to allow for the dish of the wheel. The dish of the wheel is the degree in which the spokes lean forwards/outwards, this gives the wheel a dished effect and allows for a massive increase in lateral strength.

There are a few things required to cut bevelled mortices by hand, a mallet and sharp chisel, a brace and bits (drills) a whalebone gauge, straight edge and plenty of patience! A whalebone gauge is a straight stick mounted to the front face of the nave/hub used to accurately measure the point at which the spokes should meet the fellows (the curved wooden outer sections).

The process starts with drilling holes into the nave to remove the bulk of the waste wood from the site of the mortice. The chisel is then used to roughly chop out as much wood as possible before paring the edges down gently, checking alignment with the straight edge. Any errors here could make the spokes end up pointing all over the place, leaving the wheel extremely wonky!

Morticing the nave without the pressure to produce was great fun, back home a job like this would be a real chore, only because my livelihood depends on producing in as fast a time as possible. Working here as a guest has been great, although I find it hard to step back, unwind and enjoy the experience without the urge to get stuck in, not that I was making mortices at anywhere near a productive pace as I am so easily distracted.

Tomorrow we will be straking wheels! Can’t wait to have a go, it’s a rare opportunity back home so it will be great to see how they do it here…

Today started as the days before with a stroll through the town. There are still so many sights to take in and places to visit, I am easily side tracked into conversations with the various staff I pass en route to the Wheelwrights shop. The fact that most of the historic trades staff know of my project is great, and they have all been so welcoming and supportive, every trade shop in the town is fascinating and I only wish I had more time to spend at Colonial Williamsburg.

My initial plan was to stay until yesterday (Tuesday) but I felt there was so much more to see! thankfully the Wheelwrights here are great hosts and are very happy to put up with me for a few more days, although my schedule will have very little room for error if I am to make it across to Washington state on time.

Today’s task was to strake some wheels… here comes the technical talk…

Straking is the process of fitting Iron strakes to the wheel, the strakes are shaped to fit the outside profile of the wooden felloes (curved outer sections of the wheel). Generally a wheel has one felloe per two spokes and one strake per felloe i.e. a twelve spoked wheel would have 6 felloes and 6 strakes. The strake is heated up and nailed to the felloe with large strake nails then cooled quickly causing it to shrink and tighten the wheel. each strake is placed across the joints in the felloes allowing them to pull the joints up tight as they shrink.

As with hooping wheels I find that straking is an exciting task, almost like the adrenaline sport of Wheelwrighting, it has to be done fast and with absolute accuracy…

I was honoured to be a nailer, the more exciting part of the job, albeit amidst acrid smoke and steam! nothing I can’t handle but it still makes it hard not to screw your face up…

It was great fun to work with a group of talented tradesmen, we had quite a crew assembled for the straking, all working together like clockwork…

To celebrate a successful straking we went out for a beer, and essential part of the job in my opinion and a great chance to unwind and chat with my peers.

With there being so few Wheelwrights left nowadays it is great for me to be able to meet and discuss my work with people of a similar age and attitude to the trade, especially over a few beers! … and it may have turned into a late one! hopefully tomorrow won’t require noisy tasks of any kind…

Thanks to Fred Blystone for the straking pictures.

Today was my last day in Colonial Williamsburg, the hotel like the rest of the town had started to feel like home and it was sad packing up and checking out. I was excited to spend another day in the Wheelwrights shop but saddened that it was my last, not only that but when I return (and I most certainly will) it could be at least a year down the line.

John, the Master of the shop, had a great job lined up for me today, chopping out some Elm nave/hub blanks. It’s probably about time I actually got stuck in and made myself useful as I have spent the majority of my stay relaxing and chatting away.

Part of my project is to research the materials used here by other wheelwrights, getting to work with the local Ash, Oak and Elm has been great and has given me a good understanding of the quality of the timber available here. Presented before me is a stack of beautiful American Elm, the task today was to remove the bulk of the sap wood and all the bark. To remove this you can split it away using a wedge or axe and a sledgehammer, or chop it away with a side axe… Cue the beautifully hand made Colonial Williamsburg side axe I was presented with at the weekend!…

American Elm in my opinion is so very similar in looks, toughness and quality to good quality English Elm. The only difference being that despite Dutch Elm Disease having a foothold here in the USA there is still a plentiful supply of American Elm in this area. Back in the UK the disease has had such a detrimental effect on the Elm population that We (as Wheelwrights) struggle to maintain any stock and have been forced to search for viable alternatives.

The side axe that I am beginning to grow used to takes very little effort to remove great chunks of the sapwood, despite a ‘minor’ hangover. This Elm is green and is a very recent victim of Dutch Elm disease, not that the effect has been detrimental to the quality of the wood itself. Green timber is always a joy to work as it chops like butter in comparison to dry or seasoned wood. If only I had access to such beautiful Elm back home, I find great satisfaction in helping chop out these blanks in the knowledge they will be used for some great projects here in years to come. John said something interesting whilst chopping, “I probably won’t get to use these blocks of Elm” A sad thing to hear but also inspirational as despite his eventual retirement John is still dedicated to ensuring materials are ready for whoever takes the reins and continues the never ending task of producing and maintaining the many wheels and vehicles used here on site. The general consensus on drying timber is a year per inch of thickness so in the case of some of these blanks they could still be drying in 10 years time!

Parting ways at the end of the working day was tough, these people I had known before as ‘Facebook friends’ had now become real friends. Working alongside them in the workshop and taking time to socialise together has been an amazing experience that has inspired me in my own work. To see how the system of Master, Journeyman and Apprentice has worked here has made me feel much more confident about the apprenticeship scheme I have signed up for back home and has made me feel more positive for the future of Wheelwrighting in general.

I would like to take the chance to thank the Wheelwrights of Colonial Williamsburg for their help and support during my project so far, not only during my stay with them but by also assisting me in my forward journey, hospitality that will never be forgotten!

Thank you John, Paul and Andrew for an excellent time. (not forgetting all the other wonderful staff at Colonial Williamsburg).

Next stop Pennsylvania and Ohio…

After a day’s travelling from Colonial Williamsburg, Virginia to Pittsburg, Pennsylvania I settled in to the hotel for the night. the sheer distances I will be covering between stops will be tiring but if there’s anything out there as inspirational as what I have experienced so far then it will be worth the effort. On the morning of day eleven I was met by Blacksmith Jymm Hoffman who had kindly offered to be my host for the day. Jymm contacted me through social media after hearing about the project and offered to take me to visit an Amish wheelwright he has used in the past. I jumped at the opportunity to visit an Amish Wheelwrights shop, this is not only a rare insight into an interesting community but the chance to see a Workshop that could be quite alien to anything I have seen before. The journey to the Wheelwrights shop over the border into Ohio was a great chance to chat with Jymm about life and work in general, it sounds like he gets some really interesting commissions. Jymm is an avid historian and much of his work is for museums and reenactment groups, it was interesting to gain an insight into his business as I do work along the same lines in the UK. As we neared the Amish shop it was fascinating to see the grooves warn into the roads by continous horses hooves trotting here and there with the typical buggies in tow. Everyone we passed on the road took the time to wave at us in politeness, the area was well maintained and clean, this looks a heavenly place to me.

Upon arrival at the shop we were greeted by Melvin Stutzman, he was good enough to direct us straight into his workshops and to conduct a tour. Immediately my mind was blown just by the amount of buggy wheels stacked outside the building awaiting repairs. Then there was the workshops, the metal shop was very tidy, the various metal sections neatly racked up in place and the bulk of the area kept clean (maybe it’s about time I made my shop a little more organised). The biggest thing to catch my eye as we entered the building was the massive tyre setter taking up a sizeable area of the shop. A tyre setting machine is used instead of heating the tyres to get them on the wheels. The method I use back home is to make the tyre smaller than the wheel in circumference then heat it in a fire so it expands then put it over the wheel and cool/shrink it quickly with water. The setting machine eliminates the need for this process as you simply make the tyre fit over the wheel and the machine crushes the tyre onto the wood using pneumatic rams.

Once the Wheelwrighting chat was in full flow Melvin showed me his Felloe bending machine, this in my opinion was an absolute masterpiece of home built machinery. The Stutzman’s had built this bending machine from scratch in their own shop and it was brilliant! As anyone who has steam bent timber will know it’s not that straight forward, especially when achieving curves as tight as the ones encountered on some of these wheels.

The Stutzmans had a machine for every task, in fact it soon became apparent that this is probably the most advanced wheelwrights shop I have ever been in. There was good reason for this, it turns out they can handle up to as many as 200 wheels in a couple of weeks! I would be doing well to produce or repair that many in a year. Some of the work they encounter includes everything from wooden car wheels to bicycle wheels, buggy wheels and alike, they even had some rather large chandelier wheels in ready for collection.

It was great to experience the Stuzman’s shop, an opportunity I am glad to have taken. The sad truth is I expected them to be very old fashioned and maybe even behind the times (if that term fits?) but in fact they are more than equipped to make or manufacture wheels in a big way.

On the way back to the hotel Jymm, my excellent tour guide and host offered to take me to his workshop to see the setup he uses. Another opportunity not to be missed! Wheelwrighting in traditional village life goes hand in hand with Blacksmithing, there generally can’t be one without the other. In ‘modern’ Wheelwrighting the tendency is to do all aspects in house so anything you can learn about either side of the trade is a bonus.

Jymm has an interesting shop based out of an old factory, his workshop is nestled in this interesting site, surrounded by big industrial buildings. He has an interesting modern setup (especially compared to Colonial Williamsburgs smithy) equipped with power hammers and gas forges.

After a tour of the workshop Jymm fired up a forge and offered to demonstrate how he makes strake nails like the ones I had used with the Colonial Williamsburg Wheelwrights a few days earlier. Watching him make the nail in only a single heat was awesome, the speed and accuracy with which he used the power hammer was a testament to his experience. It had been many years since I had used a power hammer, these beasty machines are the big boys toys of many blacksmiths dreams. Obviously when Jymm handed me an apron and said “now you have a go” I was extremely apprehensive! but also very excited. After a slow tentative start on the machine I manage to draw out a nail (and what a nail it was)… Then came the next challenge, whilst chatting in the car I had mentioned my lack of experience at fire welding, Jymm had obviously taken note as the next demo was chain making! First of all Jymm made up a couple of chain links. It was then up to me, it was nice to have the tuition of an expert. If anything I found the welding work far easier than I had hyped it up to be, the welds were all neat and tidy.

At the end of such an exciting day we celebrated with an ice cold beer in a local bar (well earned in the heat of the smithy). The chain and nail are safely stowed in my suitcase, ready for exhibition when I return home. Next stop Kentucky……

Travelling from Pittsburgh to Kentucky was an interesting journey, the terrain changes little but the farms and architecture varies in style from town to town, farm to farm. Despite the distance I am still enjoying the travelling part of the project, I would like to think it is giving me a greater insight into American life. It has certainly struck home the sheer size of the country, where did people even begin when it came to settling this massive continent?

After a quiet evening to catch up on my blogs and social media I was refreshed and ready to tackle the next day. The next visit was to Harley Chandlers Wheelwrights shop in Kentucky.

This shop was another last minute find with thanks to the help from the Wheelwrights at Colonial Williamsburg. I found myself in the middle of nowhere down a quiet winding road with only the odd house dotted here and there, I like isolated places but this place was like going off the map. The countryside was stunning, more trees than I am used to back in the UK. After overlooking the workshop on the 1st pass I managed to bump into one of Harleys brothers further up the road, he soon directed me back to the workshop where Harley was waiting to meet me.

Almost hidden from the road this Wheelwrights shop, surrounded by trees and undergrowth in the stunning Kentuckian countryside was a gold mine of Wheelwrighting memorabilia. Before I even had the chance to say hello to Harley my eyes were opened wide by the vast amount of tools hanging on the walls and ceiling. There was barely a space between them, far too many to list or even to see them all in one visit!

Harley, an elderly gentleman, was extremely pleasant and seemed very happy to welcome me to his workshop. After a quick introduction and chat about the trade I was whisked off around the shop on a guided tour. I found Harley was very proud of his workshop and the work he produces. He had just built a beautiful set of coach wheels for an open museum, he was also building the coach, all the metalwork and bodywork in house, fascinating to see.

Much of the machinery in Harley’s shop was ancient but extremely well maintained, he had obviously dedicated many years to collecting and restoring these machines, he had also built some machines himself just like the Amish Wheelwrights, a testament to the dedication and skill within our trade.

A true font of knowledge with a brilliant collection, I would be more than happy to visit his place again in the future.

Next stop Minnesota…

Travelling from Champaign, Illinois to Marshall, Minnesota was one long day of driving. being in the car for 11 hours straight was punishing but still interesting. The countryside had really started to transform from wild forests dotted with farmland and houses to a uniformed undulating landscape covered, as far as the eye can see, with crops of corn and cereals. The weather had thankfully settled after the most amazing lightning storms over night, the likes of I had never experienced before, the claps of lightning shook the buildings like an earthquake or a passing train!

After a well earned rest at a last minute bargain of a hotel (this one even had an indoor pool) I set off to a nearby town called Walnut Grove.

Walnut grove (as some may remember) was the childhood home of Laura Ingalls Wilder and the scene of the television series based upon her life. Laura Ingalls Wilder was a settler in the late 1800’s when the prairie was still a wild place. Trains had yet to conquer the vast expanses of wilderness and living, travelling in this time would have been a real challenge.

I was hoping that this visit would not only be entertaining but would give me an understanding of the needs of the period vehicle wise. Ok, I admit, I used to enjoy watching ‘little house’ on a sunday at grandads as a child and there was a great deal of ‘oh wow i’m actually here’ during the visit but the museum and site really hit home the isolation they endured all over the country at the time. Even timber was scarce as it either had to be hauled by horse and wagon or found locally. In this area trees are scarce and generally scrubby.

The 1st home of the Ingalls-Wilder family was a sod house, cut out of the ground to provide insulation and the walls made of turf. They would have carried everything they owned with them on a horse drawn wagon, this would then have to be put to use as a work wagon or farm wagon once they had settled… Back to the project a little here, the wagons are very basic, a pole wagon type construction underneath with straight sides and floor, there would then be a canvas sheet over the top to keep the contents safe from the elements, in the heat of the day the sides could be rolled up to let air move through. The children would often ride in the wagon on top of all the various chests of food, clothing and tools etc. If you think a road trip with kids is hard now I can imagine it was much tougher back then!

I would recommend a visit to Walnut grove, not so much to see the wagons but to develop a better understanding of what people were up against back then. There is a site just outside the town on the banks of Plum Creek where the sod house is believed to have once stood. An isolated but stunning place of calm and beauty that gives you a real taste of how wild this wilderness could really be.

Next stop Mitchell, South Dakota…

Day 16 was another day of travelling and catching up on correspondence, it’s surprised me how much organising it has taken between visits. The road to Mitchell from Marshall was near enough a continuous straight road, ideal for eating up the miles!

On day 17 I had arranged to visit the Hansen Wheel and wagon shop just north of Mitchell in South Dakota. This meeting was organised last minute after I was recommended to visit by a few other contacts from the project.

Upon arrival at the shop I was impressed by not only the beautiful setting but by the sheer size of the workshops. This place was massive! Doug Hansen Proprietor of Hansen Wheel and Wagon had been kind enough to offer me a tour of the shop, an opportunity I am very happy to have been offered. Within the shop there are several workers in various areas, as well as full time office staff, something I never expected to see in my lifetime. It’s great to see such a big wheelwrights shop thriving in our day and age.

The variety of work undertaken here was vast, not only wheels of course but also beautiful coaches and carriages, chuck wagons and alike. Watching the various professionals working away on various tasks was great, Coach building, Wainwrighting, Blacksmithing, brake assembly and of course Wheelwrighting all going on around the shop.

I have the feeling that not only the quality of the work is the reason the workshop is so busy (although the work I was seeing was top notch and a great selling point!) but it was also a testament to a good businessman. The range of on the shelf stock was breathtaking for a one man band Wheelwright like myself, everything from pots and pans for use on chuck wagons to basic wheels for chandeliers.

After meeting the rest of the team and a fantastic tour of the workshops I had the chance to talk to Tim Hoffman the Wheelwright. Working here as a Wheelwright for around 15 years he had a great wealth of knowledge about wheels and all the various styles, as did Doug. As I have found at previous Wheelwrights shops, here they find great satisfaction in making wheels! I’m happy it’s not just me, hopefully this passion for Wheelwrighting will ensure the future survival of the trade?

I found the production process here quite similar to the way I do things back home albeit much more efficient. I have finally found somewhere that has a hard time getting good timber, they have a good stock ahead of them but there is no local timber resource here. Trees in this area of South Dakota are few and far between so their timber has to be shipped in, similar to my situation back home.

After a great visit to the workshops Doug showed me to their gift shop… Yes a gift shop! I was so impressed, they had all sorts of books and memorabilia, my dreams of a working museum back home might not be particularly un realistic? This visit like all the visits before was inspirational and I would recommend visiting their site at www.hansenwheel.com

Next stop who knows?… I have a few days in the area to visit some amazing sites… keep an eye out for the next blog coming soon!…

After an exciting visit to Hansen Wheel my mind had been left buzzing all night. As with all the shops I had visited so far I had been inspired! Not that I need inspiration to ensure I continue my trade, Wheelwrighting is my passion and my life. Though it is nice to have encouragement from time to time, maybe there is more to the job than just about scraping a living doing something you love?

Today I awoke excited for a busy day at a museum, The Dakota Discovery centre was one of the 1st places on my list when I initially looked into the journey west and it had still made the final cut. Not that any of the places I couldn’t visit looked less desirable, only this place had a great website, was very close to Hansen’s shop and dissected my journey nicely.

One of the great things about this museum was the lovely heavy wagon out front, an instant eye catcher for me (I’m like a magpie for wooden wheels, wagons etc). Inside the museum I was greeted by an extremely friendly and helpful member of staff who not only pointed out the parts of the exhibits that might interest me most but went out of her way to put me in contact with a local Blacksmith. I have found everyone so helpful here in the states, the warmth, kindness and the willingness to share knowledge and experience has been essential to my project so far.

Inside the Dakota Discovery Centre is an interesting selection of exhibits depicting both Native American history and the later history of European settlers. I am finding both fascinating at the moment, especially as most of what I learned at school in the UK looks to have been complete rubbish… There is an interesting timeline theme running throughout the museum, this was great to see as it really put everything into perspective, the history of settlement here is so short. I have tools that I use in my workshop regularly that were around when the settlers on the plains were fighting with the natives.

Part of the collection that really caught my eye was some old felloes (curved outer sections of a wheel) believed to be from one of general Custers wagons from his 1874 Black hills expedition, still just about intact. The thought that went through my mind was ‘finally some attention paid to the wheel’. Throughout history empires have been built with thanks to such humble things as the wooden wheel yet it barely gets a thought when it comes to telling the stories of these great empires etc… Ok Wheelwrights rant over…The museum does have some beautiful wagons on display, all kitted out with provisions for the hard journey west. Add to that an original thrashing machine and I could have spent days there taking notes.

Next stop Clark Martinek’s Smithy (only a couple of blocks away)

After a quick drive around the block from the Dakota Discovery centre I found myself at a workshop tucked away in a suburban alley. This place was interesting from the moment I spotted it, a forge set up outside, a massive metal workbench and a vast array of metalwork loitering around the doorway, it almost felt like home.

Working away inside the workshop I found Clark Martinek and his friend Freddy Rodriguez, a visiting Blacksmith from Columbia. Inside this place was like the Tardis, there was so much to see in a relatively small space. My timing could not have been any better as the forge was stoked and ready to go, what was going to be a quick visit soon grew into an international play in the forge!

Clark’s work was interesting to see, he tackles most jobs but by the looks of things his bread and butter work is decorative items. Freddy, who came across quietly confident is a fire welding genius who has an amazing talent with welding various metals in the forge.

Getting to meet these two fantastic Blacksmiths was a great opportunity, especially when it was time for a beer… Remembering that the forge was still alight I was invited to ‘have a go’, obviously under scrutiny as a visiting tradesman. I was, of course, shy and happy to watch Clark and Freddy work first. We had been discussing various welds with different metals and got onto the topic of welding coins together… not naming any specific denominations or currencies… Some coins are rumoured to weld together easily in the forge as they have high quantities of nickel in their alloy. So we found some coins and had a go, Freddy’s weld was of course the most successful, this man knows his fire welds! Never using flux he still manages a perfect clean weld every time! Flux is generally used in most forms of welding to help produce a clean weld, something that I thought was a necessity with fire welding and I have been truly surprised to see this is not always the case.

After successfully welding a mixture of copper and nickel coins together into a billet Freddy then forged it into a beautiful horse head pendant (and then gave it to my fiancee Emily, putting a massive smile on her face).

It was then Clark’s turn to make something interesting, a scorpion bottle opener. I had seen one hanging around his workshop and admired the intricacy of the work required. Clark of course said it was easy to make these, and he did make it look easy (in the way practiced tradesmen do). The whole thing was forged from a lag bolt, an ingenious way of achieving the legs and the required amount of metal to shape the head etc. I was lucky enough to be handed this as a gift, along with an iron billet taken from an old Rockafella wheel tyre. British Airways are going to give me some strange looks when they x-ray my case on return to England, as I have been gradually gathering an eclectic mix of gifts along the journey.

Now it’s my turn… and there was no way out of this! I had decided to make something I was quite comfortable at making back home, a bodkin arrowhead (there is probably nothing more straightforward to make so little chance of getting this wrong). Back at home I would use 8mm (5/16″) round bar but here steel stock is quite limited and Clark only had 3/8 to hand (which is slightly larger). No problem though as within a few minutes I had completed a couple of arrow heads, albeit a tad wonky (no excuses but the larger steel threw me a little). As I also found whilst working with Jymm Hoffman, it is strange picking up and using someone else’s tools but still a great experience.

As the forge cooled down and the conversation heated up we sat around in the workshop with a (well earned) cold beer and Clark’s wife and brother. Time flew and before we knew it was late evening and time to leave ready for an early start travelling the next day. I had a fantastic time and it was an experience I would be eager to repeat in the future.

Next stop The Journey museum, Rapid City…

Today was another chance to enjoy some beautiful scenery whilst travelling this vast country. Whilst heading towards the site of my next visit I found myself passing through the Badlands. The Badlands are an amazing site sticking out of the prairie, pillars of soft limey rock visible from many miles away, leading your eyes towards them in curiosity. I was lucky enough to have time for a (very short) walk through this awesome place.

This must have been quite an awesome site for travellers heading west, a welcome break from the hundreds of miles of repetitive terrain on the way across South Dakota.

In the evening I settled in to another budget motel in Rapid City and thought about the next visit to the Journey Museum. I think it’s quite apt to have a ‘Journey Museum’ in the project as this has been one epic Journey so far!

This morning was yet another beautiful sunny day, I think the good weather must be following my journey so far as it has only rained on me twice over the last few weeks. I don’t know if it’s a case of fortune favours the brave, good Karma or just sheer luck but I ain’t complaining!

Arriving early at the Journey Museum on Labour day (a popular holiday here) I looked up in awe at the beautiful building. They don’t do things by half over here!

Inside the building was well set out with a theatre in the middle. There was a really interesting timeline showing the ages and positions of all the layers of rocks in the area. The bulk of the displays depicting the various local finds from different periods of history, dinosaurs through to modern.

There wasn’t much to be seen here as regards Wheelwrighting or vehicles, there was the odd wagon etc dotted about but with no massive significance. There was however a massive nave/hub on display. This I found interesting although it was not original and was only a prop from outside a shop (before donation to the museum), it was an interpretation of an original timber wagon wheel. Similar to a timber bog back home in the UK these things would have massive wheels on them capable of crossing rugged terrain pulled by teams of horses, oxen or mules. This is the kind of vehicle I could imagine was needed in some of these harsh environments to get the job done!

Despite the lack of Wheelwrighting memorabilia I really enjoyed my visit to the Journey Museum and would recommend a visit to anyone, there are even a lot of interactive parts for kids (and big kids like me).

Now to see what else the area has to entice me!…

Today I thought it would be nice to take a look at the surrounding area a little. I have been on the road so much recently that I have neglected to experience the areas I have been passing through.

The Black Hills are famous for a few things but the most obvious is Mount Rushmore. This sculpture has to be one of the most impressive carvings I have ever seen, a true piece of art and skill. Just taking the walk around the base of this masterpiece is exhausting, I can’t imagine how hard the workers must have toiled over the 14years it took to carve the four heads from a mountain of granite.

As part of my project I wanted to experience what people crossing the USA would have been up against back in the days before interstates, automobiles and trains. A great portion of my journey is following the route of Lewis and Clark who were sent west to chart a route across the country after the Louisiana purchase back in 1803. This journey was, funny enough, ordered by Thomas Jefferson, who is one of the men whose face has been immortalised in the carvings at Mount Rushmore.

I had arranged to go out on a trail on horseback as I thought this was apt. I had found an outfitters based in the Custer National Park, another amazing, wild and beautiful place filled with wildlife. Anyone who knows me well will vouch for the fact that on the back of a horse is not my native environment. Although I was really looking forward to this opportunity and glad that it was a ‘walk only ride’ i.e. the horse should know what to do and I wouldn’t be left holding on for dear life as it gallops off into the sunset!

The one thing that really struck me whilst out on the horse was how long it takes to cover such a short distance in this rugged terrain, and that’s without hauling all your worldly goods along with you. Every incline, river and fallen tree is an obstacle to overcome. Fun when out on a leisure ride but I’m certain these obstacles would become laborious and heartbreaking after hundreds of miles of the same.

Fortunately I stayed on the horse and didn’t end up raw from the saddle, these western style saddles are great (even with the risky looking pommel on the front).

Lesson learned… everything needs to be tough over here to cope with the abuse of the terrain and the demands placed upon them. Carts and wagons would have to be dependable to the absolute extreme and that shows through the basic and rugged designs I have witnessed so far.

Next stop Buffalo Bill Centre of the West…

Travelling to Cody, Buffallo Bill Centre of the West. I have been excited to visit so many places on this journey, Cody is probably amongst the most famous sites as most people will have heard of Buffallo Bill’s Wild West show.

As has been the theme throughout it was a beautiful morning in Cody. The town created by Buffalo Bill himself is a ‘planned settlement’ and was a real taste of the Wild West (and I found the town fascinating).

Strolling through the town from my motel to the Museum was great fun. I had already explored the town the previous evening but the daytime brought out the most amazing mix of people I had ever been amongst! There were real cowboys in their glittery rodeo boots and Stetson hats to Japanese tourists with their cameras out in a stereotypical fashion.

The Museum was massive, I think this is probably the biggest static museum I have visited to date. Covering several acres on multiple floors I was worried that a day wouldn’t be long enough!

Inside, the museum was set out in separate areas per theme, and it was all fascinating, from natural history through to a firearms collection. There was an interesting collection of horse drawn wagons and covered wagons hidden away downstairs. It was great to see the wagons clustered around with all the tools and supplies on board as they would have been when they were crossing the plains. The only fault I could find was the lack of interest paid in the trades behind these vehicles etc. No focus on Blacksmithing, Wheelwrighting or any other attached trades. Is this the sad truth that these trades are near forgotten? If knowledge of the trades dies does that not mean the trade dies? I might be over focussing on the ‘forgotten trades’ but it is a topic close to my heart.

Please don’t think I have any negative feelings towards these museums, the work they do is great and their ability to hold the publics interest is priceless. I only fear the potential to forget a massive and integral part of history… Rant over …

The Buffalo Bill’s Wild West show was world famous, a favourite of queen Victoria amongst countless thousands. He brought the wild west (or at least his version of it) to the world, leaving a legacy that lasts today. Not only was his stage show a great success but his professional career as a frontiersman was most notable.

The collections housed in Cody are a true testament to the story of Buffalo Bill and the taming of the West I would recommend a visit to anyone as there are points of interest for just about anyone. I was fascinated by the firearms collection, I never imagined it could be possible to have so many different guns in one place. There was everything from very early muzzle loaders to modern assault rifles and everything in between!

Now for a lot of travelling… Wagons West once more!…

After an interesting visit to Cody I headed west again towards the wild and renowned volcanic caldera of Yellowstone National Park. My trip wouldn’t be complete without visiting the most famous feature of Yellowstone, Old Faithful. A geyser getting it’s name from it’s closely predictable spurting, approximately every hour.

The area within and around the Yellowstone Caldera was stunning, beautiful rivers, forests and hills scattered with the odd bubbling mud pool, steam vent or geyser. A magical and fascinating place in and around the Caldera of a dormant volcano, I was lucky to have passed through such a place and I would definitely recommend to visit.

After leaving Yellowstone I had a vast distance to cross to my next possible visit in Idaho. I decided to break my journey up with a stopover for a couple of nights (and I was ready for a bit of time out by this point). I had never imagined the travelling and visits could use up so much energy! I work reasonably hard for a living back in the UK, and I presumed this journey would actually be a rest… I was so wrong.

Fortunately I was ahead of schedule so far, making good time across the country, driven by my excitement to see and learn more.

I found a beautiful place in to stay in the mountains, a tiny resort called Lolo Hot Springs… it was a bargain! Situated in a stunning narrow valley, nothing more than a lodge, bar and RV park, this place was paradise for me, isolation and relaxation. The only problem was the lack of Wifi… maybe I should have checked before booking. This of course gave me the chance to go out walking in the wilderness, bear spray strapped on my chest just incase!

After my well earned break I headed into Idaho to hopefully visit another working Wheelwrights shop. Unfortunately the Wheelwright I was hoping to visit was working away. I suppose so far I had been lucky with my timing, meeting more Wheelwrights than I could have hoped.

The fact that I was now days ahead of schedule meant that I could possibly fit some extra visits in around the West coast.

Next stop Washington state and the North West Carriage Museum….

It was a long old drive across Washington state but what a beautiful drive it was!

The varying terrain from mountain passes, rivers and trees to prairies and corn fields, back to mountains kept the journey interesting. I am a great lover of mountainous scenery, clean mountain rivers and vast expanses of forest. There was no shortage of that here.

As I descended from the mountains towards the coast I found myself in a quiet little town called Raymond. This little town was clean, welcoming and almost a vision of a stereotypical quiet American town. I was glad to get settled into the motel and rest after the days drive, refreshed for the next days visit.

The place I had come here to visit was the North West Carriage museum. I had found this museum via an internet search and was hooked from day one. It had formed one of my definite stops on the journey, being on the West coast in a position ideal for me to end the journey and leave the country. In this museum is housed a beautiful collection of horse drawn carriages, in excellent condition. The collection boasts not only a wide selection of carriages but a keen interest in educating the public about the history of the carriages and Wheelwrighting.

Most of this collection contains the finer end of horse drawn vehicles from manufacturers worldwide including makers in England. Some of ‘pride of the collection’ vehicles have featured in films such as gone with the wind, a great tourist attraction that leads people’s interest towards the rest of the story behind the vehicles and history.

Within the museum is an educational area where children (and adults) can learn more about the making of the wheels, the tools used and can take part in activities. They can even dress up in period clothing and have pictures aboard one of the vehicles or have a go at steering a horse and cart (stationary model of course).

I have been really taken by this museum, not only because of the collection and location but by the attitude towards passing on history and the love for the collection. The museum is also currently under expansion with a new addition (‘extension’ back home) that will house more of the working vehicles that would have been used in order to show both ends of the scale.

The staff at the museum are passionate, friendly and extremely knowledgeable. It’s this kind of dedication and passion to the history that has made my project so exciting and interesting. Laurie, Jerry and Mary had made me feel so welcome and right through my journey Laurie had keep in touch and helped out with recommendations for places to visit and stay. As with all my visits so far I will be forever thankful for the kindness I have been shown and the great hospitality.

Leaving the Museum felt like the end of an era for my journey. Although this will not be my last stop on the journey, thanks to some welcome recommendations from Jerry and Laurie I will be heading onwards to another visit in Canada! and it sounds a fascinating place.

On the way out of the USA I have another stop or two to make that could prove interesting….

Final goodbye USA video…

After leaving the tranquility of Raymond and the North West Carriage Museum I headed to the coast. I thought it important to see the Pacific ocean as I had looked out East over the Atlantic from the shores of Virginia weeks before at the beginning of my journey. I had travelled entirely from coast to coast, east to west across one of the most expansive countries I had ever experienced.

I took the chance to reflect over my journey and all the wonders I had seen. For a quiet country lad like myself this project has bordered on overwhelming. When I initially came up with the idea for Worldwide Wheelwright I never imagined it would go so well! Although the proof is in the pudding and now it’s down to me to make the most of my experience both in my own life and in how I will make my findings useful to others. With the evening approaching I decided it might be nice to round up my video blog as the sun set over the pacific. Something I was glad I had made the effort to do. I had to hike for a couple of miles through a rarely used track down to a deserted beach at the tip of the Long Beach peninsular, I had hoped to find a decent spot to film there and watch the sunset.

Watching the sun disappear into the Pacific was awesome and almost spiritual (I hate using that word) although the hike back to the car was a little jumpy!… It got dark in the woods very quickly!

The next day I decided to head along the Olympic peninsula, this leads to the most Northern tip of the lower states and is close to Seattle where I would be flying out from.

I had heard of a small museum in a town called Forks (famous from them there vampire films) and seeing as I had a little time on my hands before flying out I thought it would be an interesting stop. The Olympic peninsula boasts one of only a handful of temperate rain forests in the world. I couldn’t possibly miss seeing that! It was stunning, and fascinating for me being a bit of a ‘tree nut!’

The Forks timber Museum was quite interesting, there was a selection of memorabilia on the timber extraction work in the area and some fantastic old chainsaws that looked so dangerous to me. There was also a half completed dug out canoe that loggers had found out in the forest, presumably started by the indigenous people hundreds of years before then abandoned. Maybe they found a fault in the timber or decided on using a slightly better tree? who knows?

Most of the timbers harvested in this area are softwoods and not really any use for my cause but it’s still interesting to see how the process works out there.

The sheer size of the trees around there is awe inspiring, at La Push beach there was a massive tree washed ashore, at least 7feet in diameter! I managed to find a small deserted beach and decided it would be nice to sit out under the stars that night with a campfire. Surprisingly enough coming from the UK where campfires are frowned upon, there fires are welcome! There are even guidelines posted up saying how and where to have your fire. Having grown up with an appreciation for the campfire and the peace that comes with just sitting by the fire this place really appeals to me.